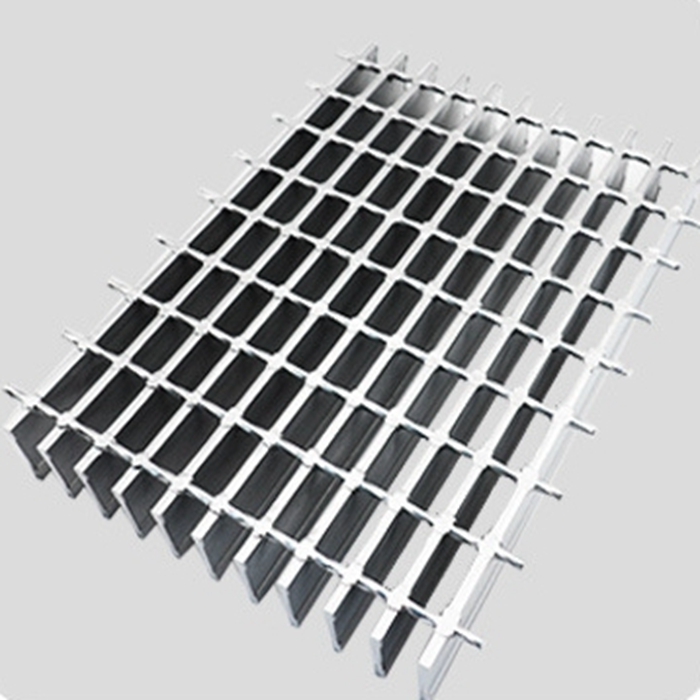

Construction Steel Mesh Steel Grate Steps Drain cover

Step grating serrated non-slip galvanized steel grate

Product description

Steel grating stair treads are ideal for many different applications. They are available in carbon steel, aluminum or stainless steel. The stair treads of each of these metal grating types have a flat or serrated surface. Can be produced according to what you want.

Our serrated stair treads are specifically designed to provide slip protection in areas prone to oil or other hazardous elements. Non-slip stair treads are ideal for industrial facilities or outdoor locations where slippery conditions may exist.

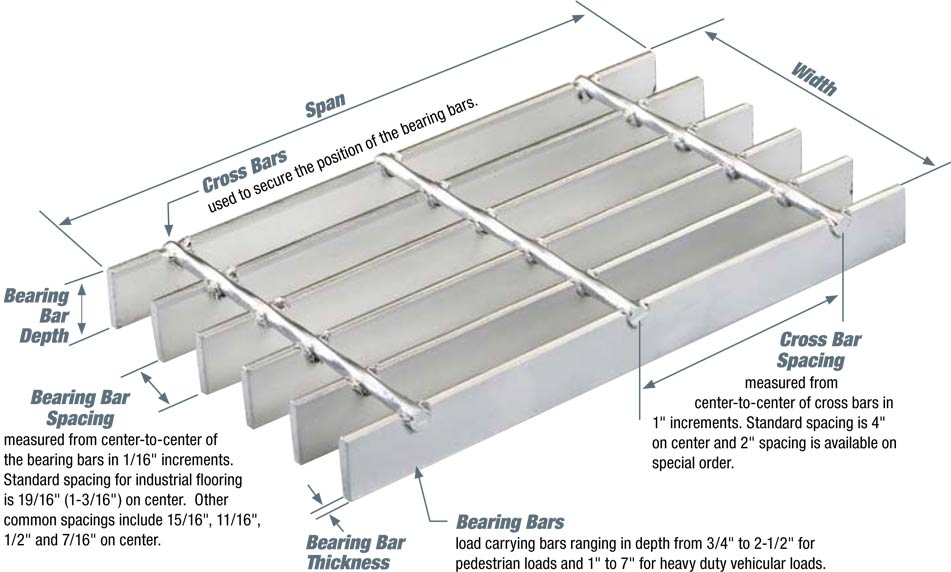

Product details

Machine pressure welding uses a high-voltage resistance pressure welding machine, and the manipulator automatically places the crossbars horizontally on the evenly arranged flat steel, and press-welds the crossbars into the flat steel through strong electric welding power and hydraulic pressure, so that the solder joints can be strong, High-quality steel grating with high stability and strength.

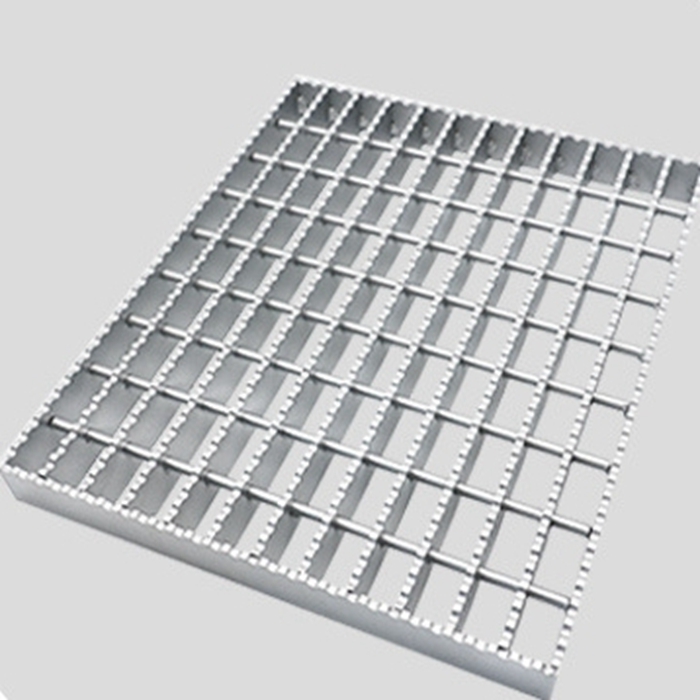

Features of stainless steel grating: lightweight, high strength, large bearing capacity, economical materials, ventilation and light transmission, modern style, beautiful appearance, non-slip safety, easy to clean, easy to install, and durable.

According to different materials, steel grating can be divided into: aluminum steel grating, stainless steel grating, low carbon steel grating

Aluminum grates are lightweight, corrosion resistant and fully recyclable. These products have an unrivaled strength-to-weight ratio and are ideal for industrial and architectural applications.

Aluminum product finishes are available in anodized, chemically cleaned or powder coated finishes, all for highly corrosive or architectural applications.

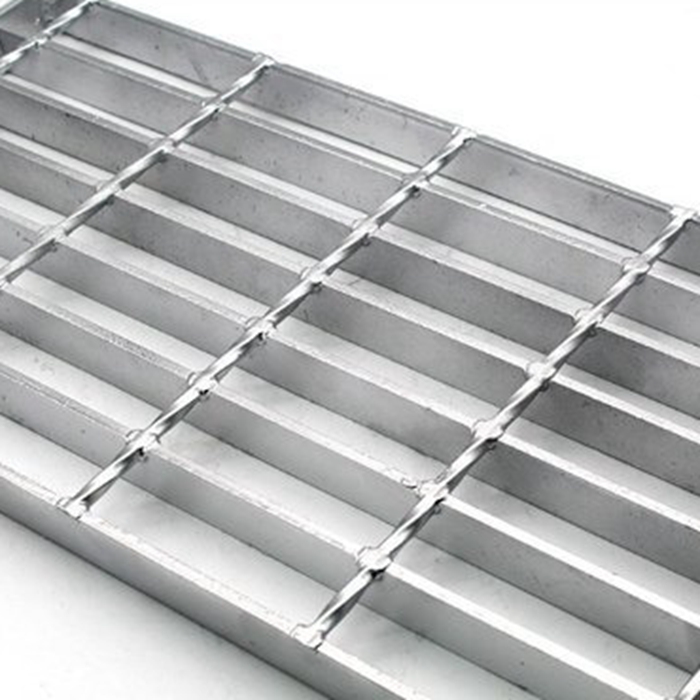

Low carbon steel grating is primarily used to serve applications ranging from light pedestrian traffic to heavy vehicular loads.

Finishing options include bare steel, painted, hot dip galvanized or specialty coatings.

Stainless steel grating materials are generally 304, 201, 316, 316L, 310, 310S

Features: light weight, high strength, large load-bearing capacity, material-saving economy, ventilation and light transmission, modern style, beautiful appearance, non-slip safety, easy to clean, easy to install, and durable.

There are three surface treatment methods for stainless steel grating: pickling, electrochemical polishing, and chrome plating. Different surface treatments can be selected according to the requirements of the use environment.

Features

The surface of the steel grating can be treated by hot-dip galvanizing and spraying to enhance its corrosion resistance and aesthetics.

Steel gratings of different materials are suitable for various environments such as kitchens, car washes, residential quarters, schools, hotels, canteens, restaurants, supermarkets, hospitals, and bathing centers.

Choose steel gratings of different materials according to your different usage environments. You can tell us your usage, and we can make a recommendation for you.

FAQ

Q: Do you offer custom sized stair treads?

A: Yes, we can manufacture regular size stair treads. At the same time can also be customized. Please call or email us your custom sizes and specifications.

Q: Is it possible to receive a catalog of your stair tread products?

Answer: Of course. You are welcome to communicate with us by email or telephone to obtain our product catalog, and you are very welcome to communicate with us if you have any questions.

Q: What material options do you have for those stair treads?

A: Stair tread gratings are available in carbon steel, galvanized, aluminum or stainless steel.

Q: Are your railing stair treads non-slip?

A: Yes, our steel grating stair treads are designed for non-slip applications, and this grating product is one of many non-slip stair treads we offer. Our serrated stair treads are specifically designed to prevent slips and falls in areas prone to oil, water or other hazardous elements.

Q: How do I prevent the metal stair treads from rusting after I purchase them?

Answer: First of all, our materials are all made of high-quality raw materials, which are not easy to rust. Secondly, during use, regular removal of debris will also help protect the stair treads for a longer period of time. At the same time due to natural factors, outdoor stairs will change over time. If you want a more anti-rust effect, then we suggest that the surface treatment of the stair treads is galvanized, which can provide the longest service life for the outdoor stair treads.

Q: How long will metal stair treads last?

A: Our metal stair treads stand the test of time, especially if they are hot dipped galvanized. It is not uncommon for galvanized stair treads to last up to 20 years, depending on the environment in which they are installed.

Q: Where can metal stair treads be used?

A: Stair treads can be used almost anywhere. Indoor/outdoor sports facilities, water parks, hotels, resorts, amusement parks, food processing facilities, chemical facilities, water/wastewater treatment facilities, etc.

Q: Which metal stair tread pattern do I need?

A: It depends on the intended location and use of the stairs. Larger holes will allow for better drainage, while smaller holes help support more weight and usage requirements.

Q: When should metal stair treads be replaced?

A: When you feel that pedaling is not safe enough, you can change it.

Q: What are the advantages of metal stair treads?

Answer: Metal stair treads are very suitable for industrial applications, such as: outdoor factories, workshops, workbenches and other areas, and can have stronger anti-skid performance. Because of the use of these metal stair treads, the number of various accidents has been effectively reduced and the safety within the facility has been improved.