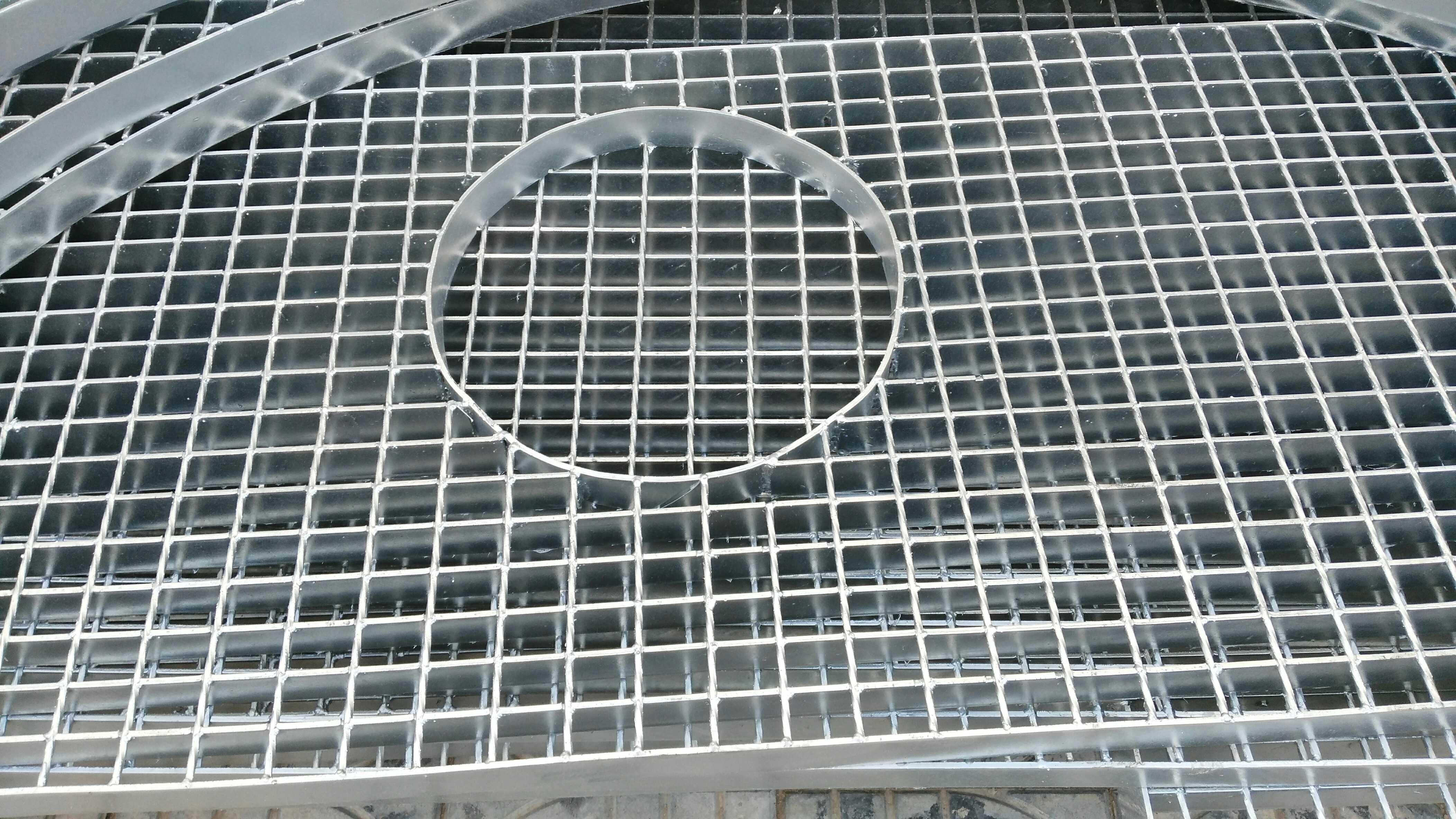

Ukuze kunwetshwe impilo yesevisi ye-gratings yensimbi, indawo engaphezulu ingaba i-galvanized ye-dip-dip, i-cold-dip galvanized, noma i-spray-pendiwe. Igridi yensimbi engagqwali kakhulu i-hot-dip galvanized steel grating. I-hot-dip galvanized steel grating iyindlela evame ukusetshenziswa ngabasebenzisi. Uma kunenqwaba yemfucumfucu ebusweni bensimbi yensimbi, impilo yesevisi ye-steel grating izofinyezwa. Isibonelo, ukungcola okusele ezitebhisini zesitebhisi kanye nesembozo semisele kudinga ukuthi sihlanze futhi sigcine izinsimbi zensimbi.

Ukugcinwa isikhathi eside kwe-steel grating kubaluleke kakhulu. Kumelwe uhlakulele umkhuba omuhle wokuhlanza nokuhlola njalo. Ngokulungiswa okufanele, i-hot-dip galvanized steel grating ngokuvamile ingasetshenziswa iminyaka engu-30 ngaphandle kwezinkinga. Izindlela eziqondile zokuhlanza nokulungisa zimi kanje:

Ngesikhathi sokufakwa

1. Izingxenye ezidinga ukushiselwa kudingeka zidwetshwe ngopende ophikisana nokugqwala ngemva kokushisela.

Ngesikhathi sokusebenzisa

1. Kugcine kuhlanzekile ngezikhathi ezijwayelekile futhi ugweme ukumbozwa yilo lonke uhlobo lokungcola, ikakhulukazi izinsalela zezinto ezonakalisayo.

2. Uma kutholakala ukuthi ungqimba lwama-galvanized alusekho, sebenzisa upende ophikisana nokugqwala ngesikhathi.

3. Amagridi ensimbi ahlanganiswe namabhawodi kumele ahlolwe njalo ukuze kubonakale ukuthi amabhawodi axegekile futhi noma yiziphi izingozi ezifihliwe kufanele kubhekwane nazo ngesikhathi esifanele.

I-Hot-dip galvanized steel grating akumele igcinwe kuphela ngesikhathi sokusetshenziswa, kodwa futhi inake lapho uthenga: ungqimba lwezinki olushisayo olushisayo kufanele lube sezingeni elihle futhi akumele kube nenani elikhulu lezingubo ezigejiwe. I-zinc layer akumele ibe mncane kakhulu (okuzothinta impilo yokunqanda ukugqwala) noma ugqinsile (uma ugqinsile, ungqimba lwezinc olungaphezulu luzowa).

Isikhathi sokuthumela: Apr-16-2024