Installation of embankment gabion net:

1: The gabion net sinking and discharging operation starts with sinking and discharging the gabion net woven with iron wire. It can also be electroplated and coated with PVC (polyvinyl chloride), and PVC gabion net sinking can also be used as bank protection and toe protection.

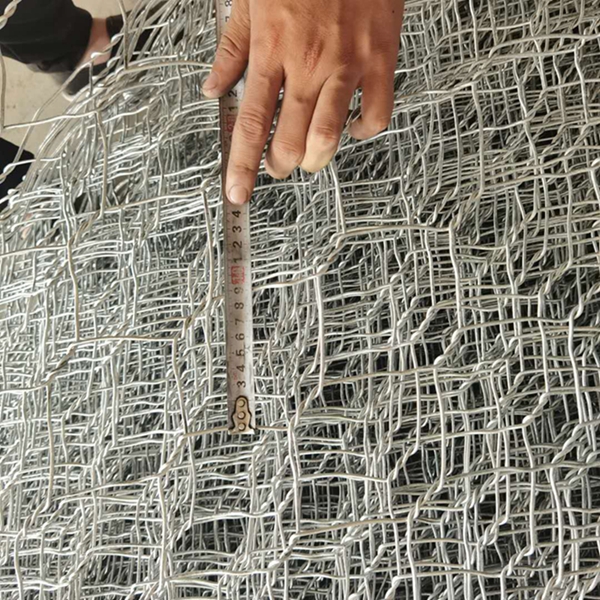

2: Stone box (box-shaped gabion). Gabion mesh is a mesh-like fabric of iron wire or polymer wire that holds the stone filling in place. A wire cage is a mesh or welded structure made of wire. Both structures can be electroplated, and the woven wire box can be additionally coated with PVC. Gridded gabions are more flexible than welded gabions and therefore have different capabilities in adapting to subsidence and loading. Rigid stone boxes are sometimes considered to be rigid, although care must be taken to ensure that the stone is packed tightly. Easier to fill, braided wire or polymer lattice structures are preferred when deformation occurs without loss of strength for non-standard shapes, such as corners, or where large sinks can occur.

3: Fill the inside of the gabion net with weather-resistant hard stones. It will not be broken quickly due to abrasion in the stone box or gabion sinking. Gabions equipped with different types of block stones have different characteristics. The multi-angular stones can interlock well with each other, and the gabions filled with them are not easy to deform. Therefore, when used in large shear-resistant retaining walls, it is more effective than round stones, and on the other hand, it facilitates the connection of gabions. The general size of the filler is 1.5 times the average mesh size. A single stone should not be smaller than the standard grid size (the size of the commonly used woven gabion is (60mm Relax minimum stone size requirements.

4: Internal filling. Mechanical filling is generally faster and cheaper, but is not as controllable as manual filling. For modified retaining walls, a better appearance should be produced and a dense structure should be formed. When using these two methods, the filler must completely fill the gabion mesh. The filler must be well packed to minimize voids, with good contact between individual stones, and packed as tightly as possible to reduce the possibility of movement of the stone within the gabion. When the filler size is within the normal range, polygonal and round stones can be packed tightly, and some soil can be added.

Post time: Apr-09-2024