ODM Anti Skid Plate Anti Slip Tread Plate Perforated Metal

ODM Anti Skid Plate Anti Slip Tread Plate Perforated Metal

Product Description

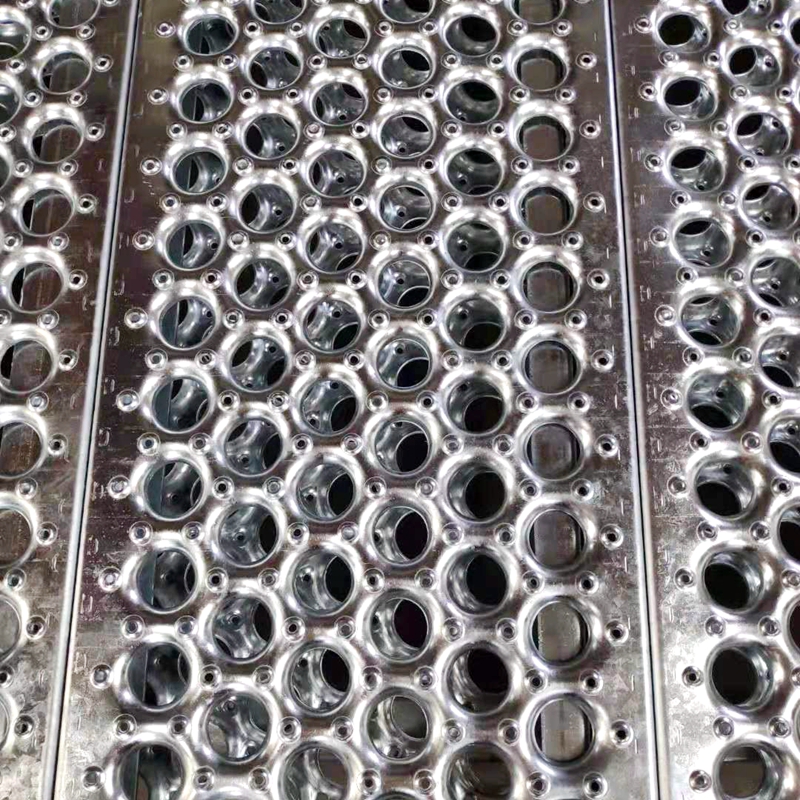

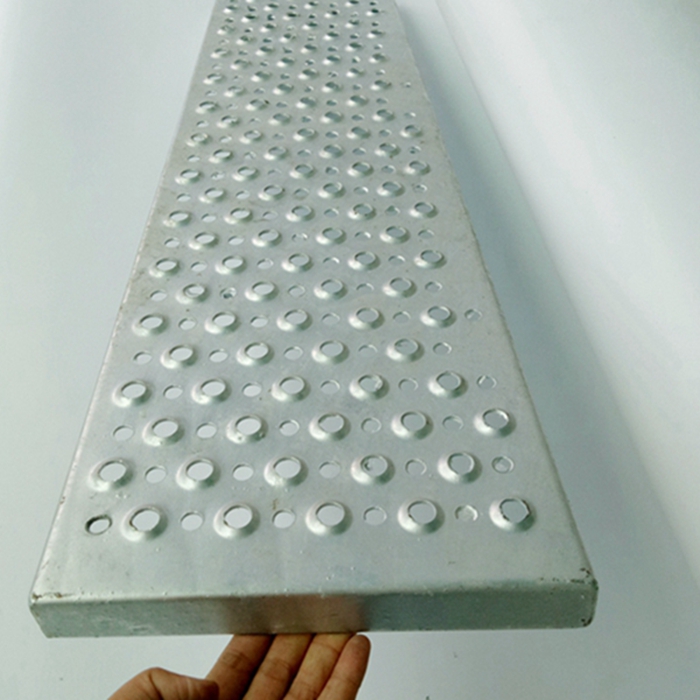

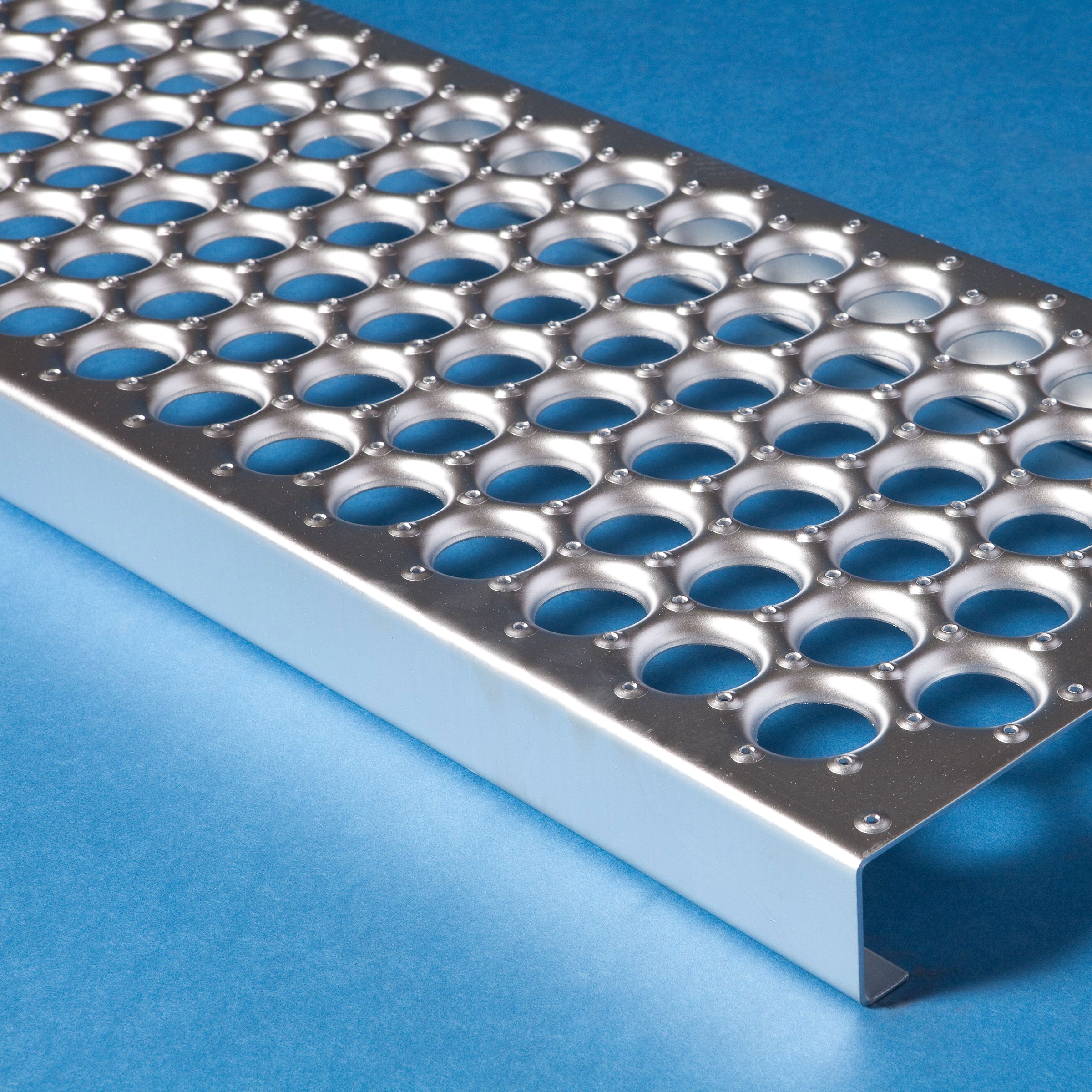

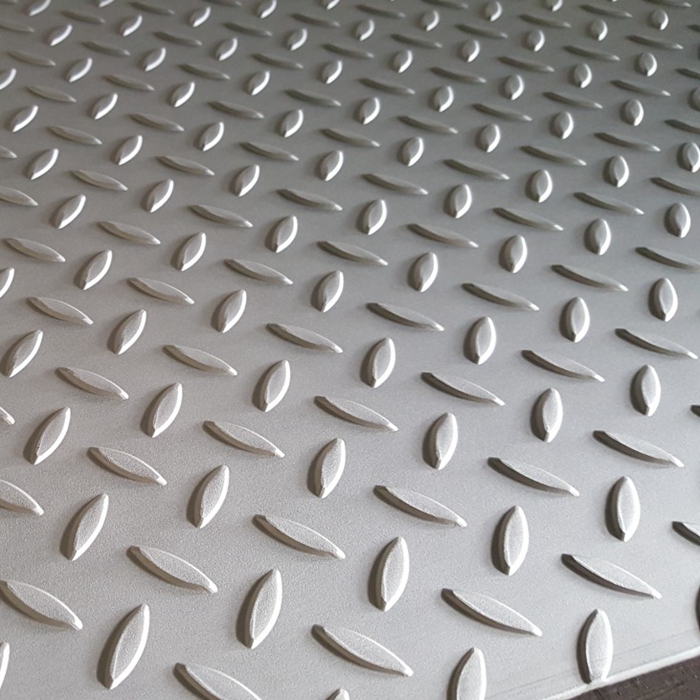

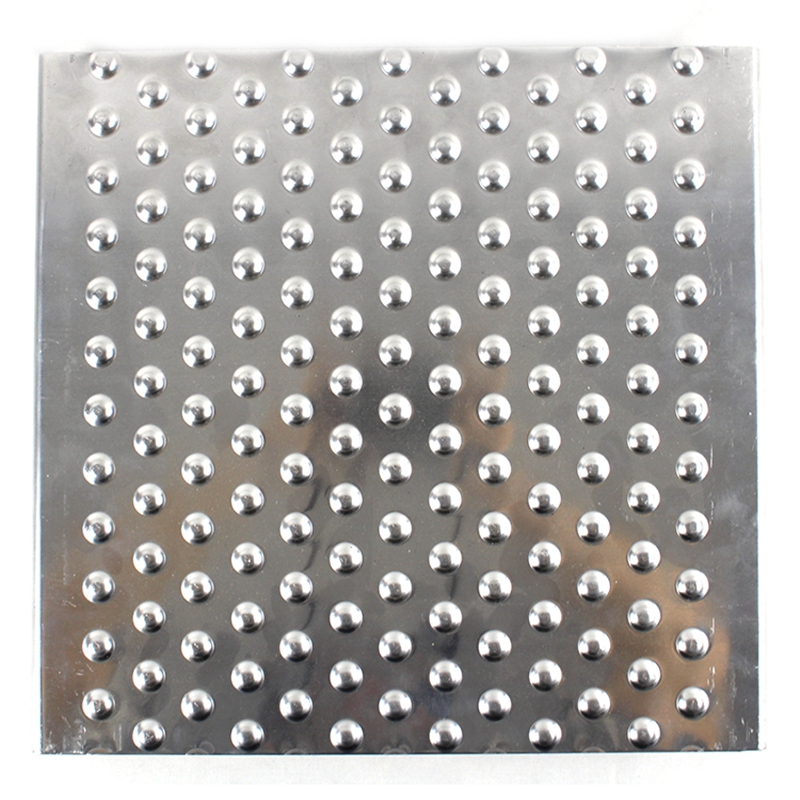

The anti-slip perforated plate is a metal plate whose main function is to prevent slipping. It is commonly used in industrial and commercial environments where slip and fall accidents are prone to occur, such as stairs, walkways, ramps and platforms.

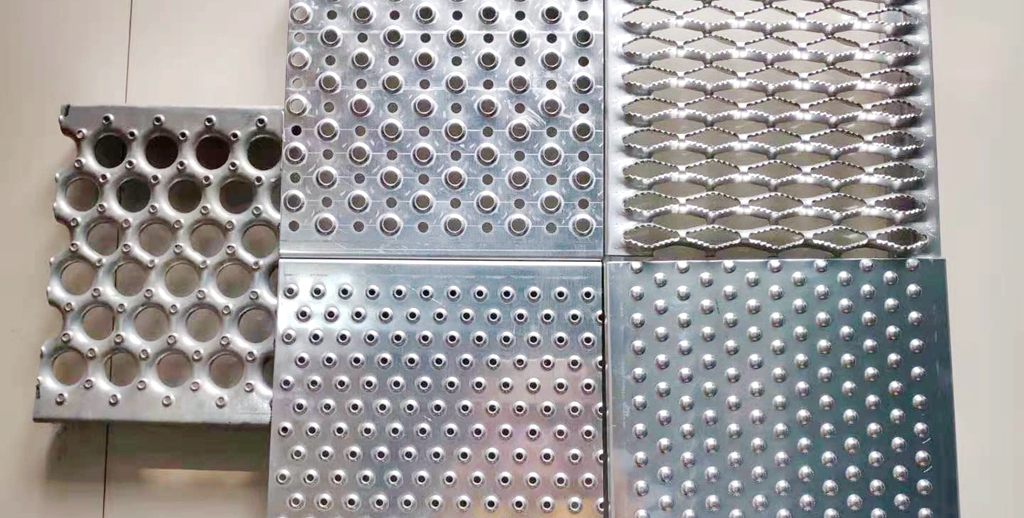

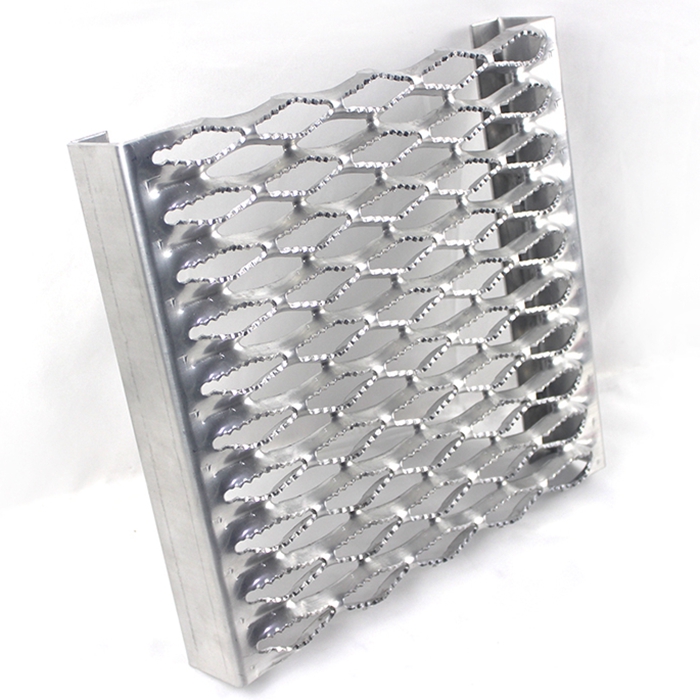

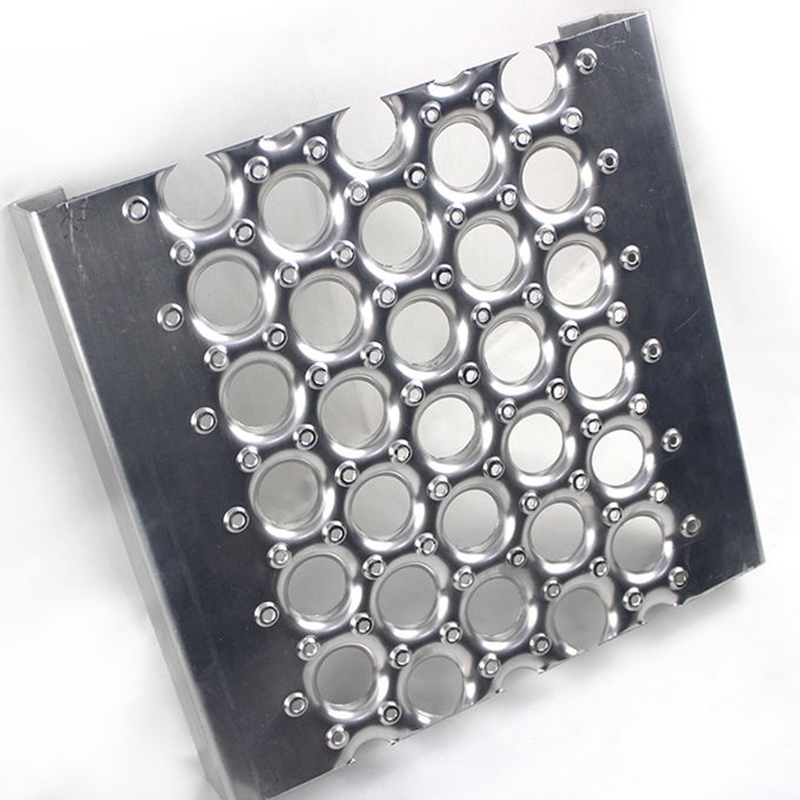

The skid plate is usually made of a steel or aluminum sheet metal with small or raised holes. Different diameter holes allow water, oil or other liquids to drain smoothly. This can effectively avoid or reduce the accumulation of slippery substances on the surface of the board and reduce the risk of accidents.

The dimensions and specifications of the anti-slip punching plate vary from manufacturer to manufacturer, and the common specifications are as follows:

Thickness: 1.5mm-6mm

Aperture: 1mm-20mm

Spacing: 2mm-50mm

Board width: 1m-2m

Board length: 1m-6m

The above are only common specifications, non-slip perforated sheets are available in a variety of sizes, thicknesses and patterns to suit different applications. They can be customized to meet specific requirements and can be coated or painted for additional protection against corrosion and wear.

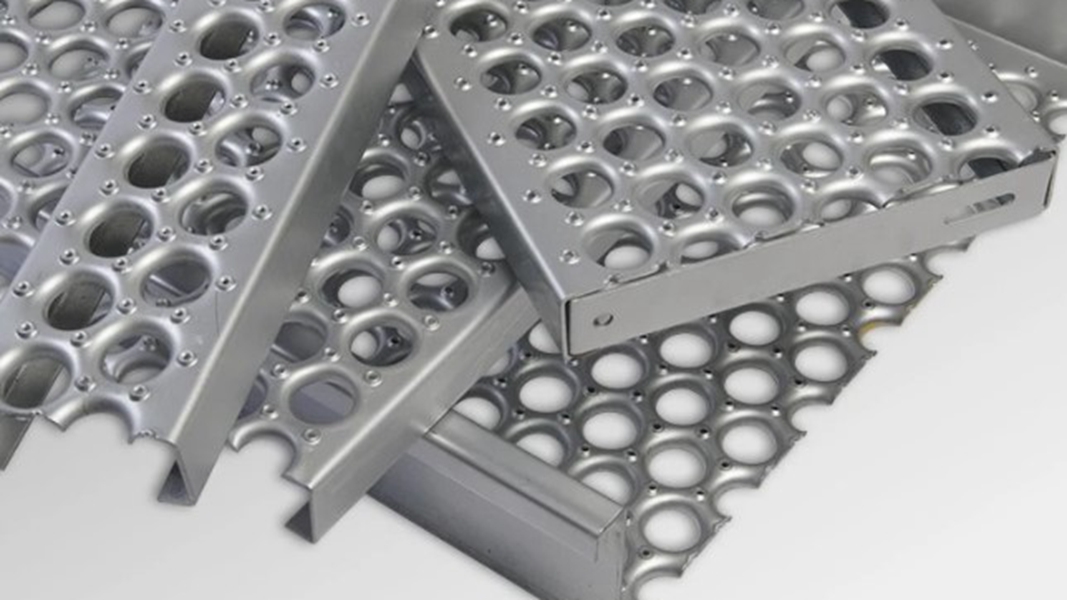

Product Photos

Application

The application range of anti-slip perforated plates is very wide, and can be used in industry, construction, transportation, agriculture and other fields. The following are the specific application scenarios of anti-slip perforated plates:

1. Industrial field: anti-slip perforated plate can be used in the ground, steps, platforms, passages, protective railings and other parts of factories, workshops, docks, ships and other places.

2. Construction field: Anti-slip perforated panels can be used for anti-slip floors, protective railings and other parts of public buildings such as stairs, balconies, corridors, overpasses, and underground parking lots.

3. Transportation field: anti-slip punching plate can be used for anti-slip floors, protective railings and other parts of roads, bridges, tunnels, subways and other transportation facilities.

4. Agricultural field: non-slip perforated plates can be used for non-slip floors, protective railings and other parts of agricultural machinery, livestock pens, agricultural buildings and other places.

5. Other fields: Anti-slip perforated plates can also be used for anti-slip floors and protective railings in stages, stadiums, parks and other places.

FAQ

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance against the copy of B/L.

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

Contact Us

22nd, Hebei Filter Material Zone, Anping, Hengshui, Hebei, China

Contact us