OEM Heavy Duty Driveway Floor Drainage Trench Cover Low Carbon SS400 S235JR Steel Grating

OEM Heavy Duty Driveway Floor Drainage Trench Cover Low Carbon SS400 S235JR Steel Grating

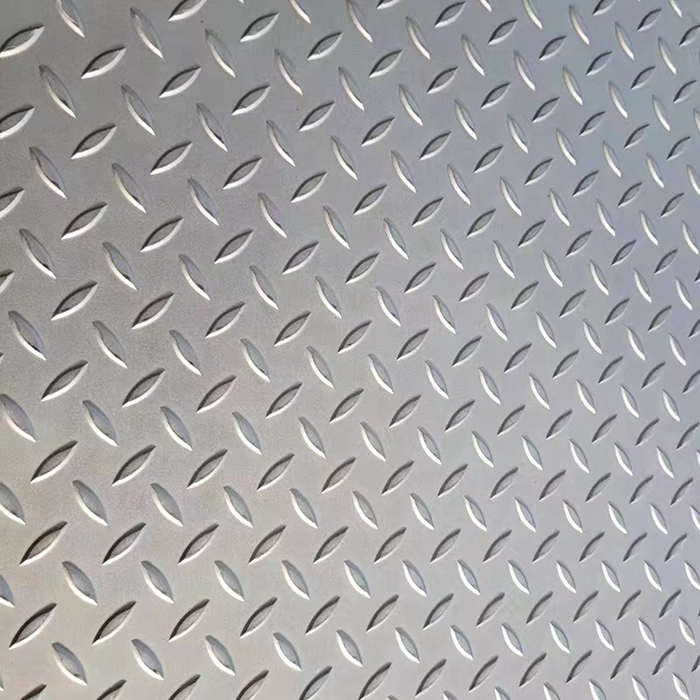

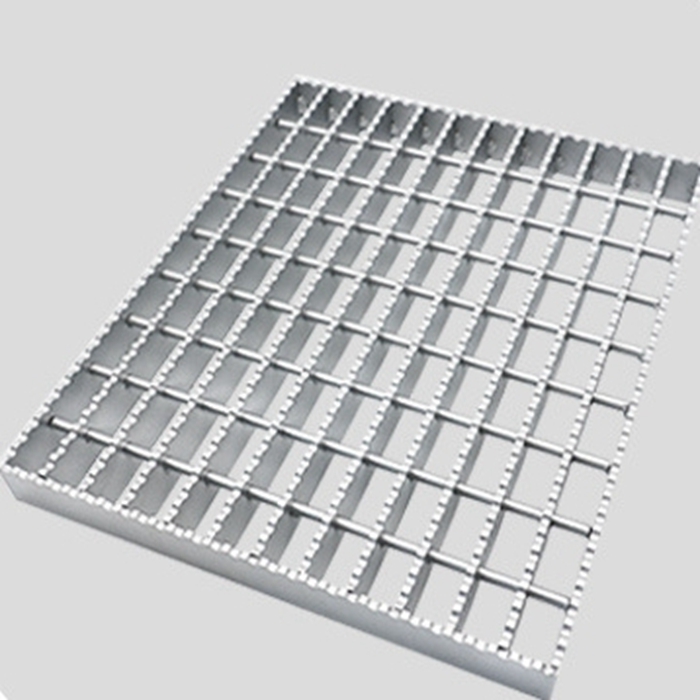

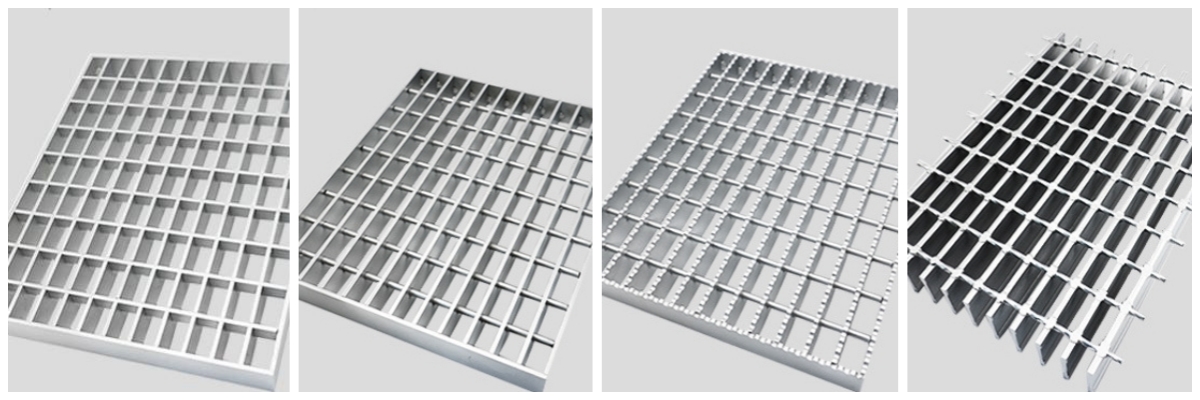

The steel grating is an open steel member that is orthogonally combined with load-bearing flat steel and cross bars according to a certain distance, and fixed by welding or pressing; the cross bars generally use twisted square steel, and round steel can also be used. or flat steel,

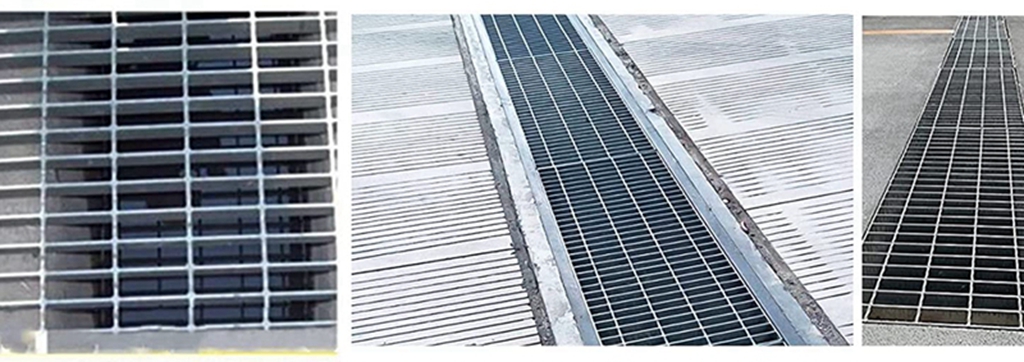

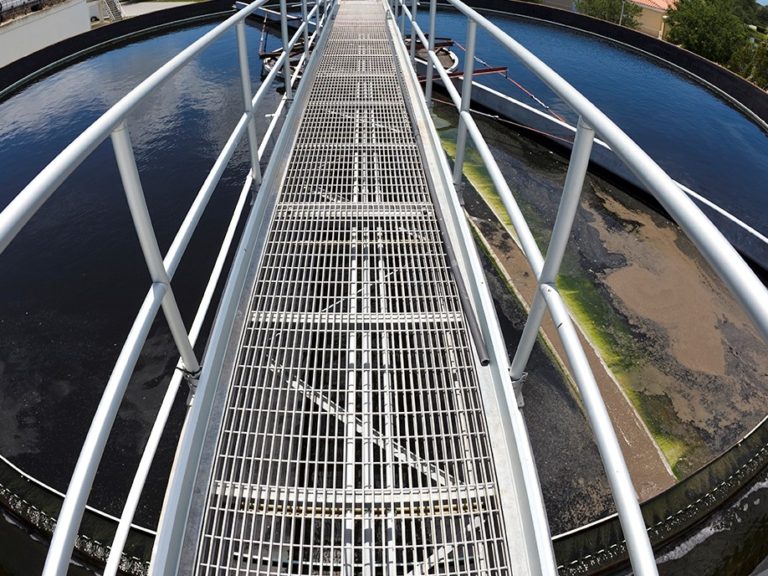

It is mainly used for steel structure platform slabs, ditch cover slabs, steel ladder treads, building ceilings, etc.

Material classification

Features

Steel grating has the following advantages:

Material saving: the most material-saving way to withstand the same load conditions,

Reduce investment: not only saving materials, but also saving labor, saving construction period, free of cleaning and maintenance.

Simple construction: convenient and time-saving, fixed with bolt clips or welded on the pre-installed support, the installation is very fast and can be completed by one person. No extra labor is required.

Durable: After hot-dip zinc anti-corrosion treatment before leaving the factory, the product has strong impact resistance and pressure resistance, and the service life is longer.

Modern style: beautiful appearance, standard design, ventilation and light transmission, giving people a modern feeling of overall smoothness.

Lightweight structure: less material, light structure, and easy to hoist.

Anti-accumulation of dirt: no accumulation of rain, ice, snow and dust.

Reduce wind resistance: due to good ventilation, the wind resistance is small in case of strong wind, reducing wind damage.

Simple design: no need for small beams, simple structure and simplified design;

If you are buying for the first time, it doesn't matter, you just need to indicate the model, we have a professional team to design the layout for you.

Application

Contact Us

22nd, Hebei Filter Material Zone, Anping, Hengshui, Hebei, China

Contact us